Hydrogen energy&new energy

Hydrogen energy is an emerging clean energy source that has advantages such as high energy density, zero pollution, and renewability. It is considered an important direction for future energy development. However, hydrogen energy still faces many challenges in storage and transportation. The bipolar plate flow channel for hydrogen energy is an important component in the development of hydrogen energy and plays a crucial role.

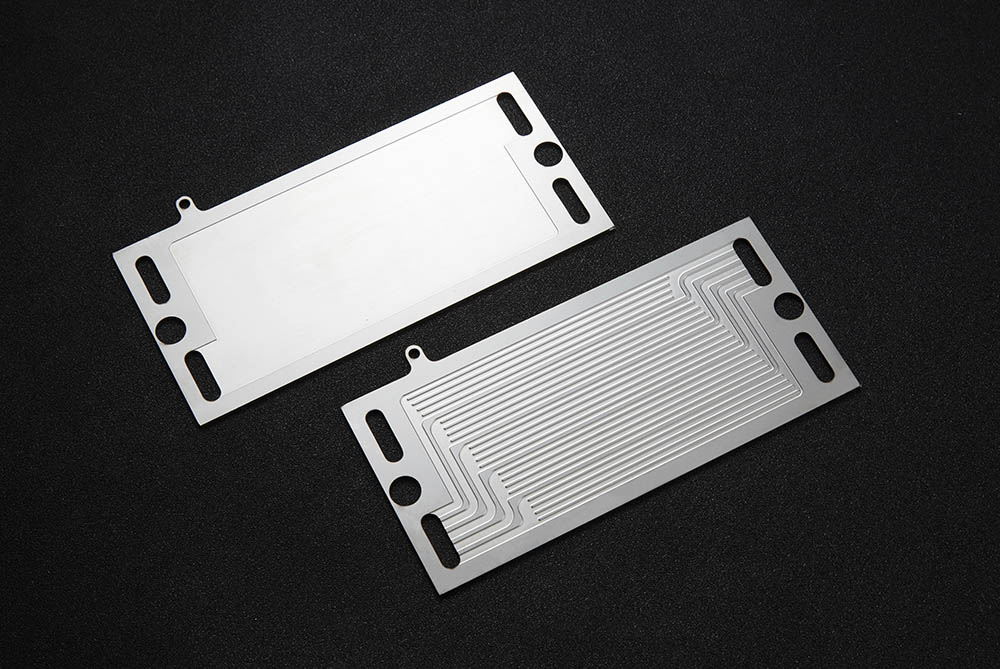

The bipolar plate flow channel for hydrogen energy is a crucial component used in the electrolysis of water to produce hydrogen. The electrode reaction decomposes water into hydrogen and oxygen, and the produced hydrogen is used for fuel cell power generation, while oxygen is released into the atmosphere. In this process, the function of the flow channel plate is to separate the reactants between the electrodes, prevent them from mixing with each other, and ensure the efficiency and stability of the reaction.

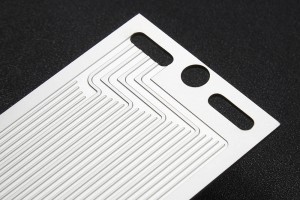

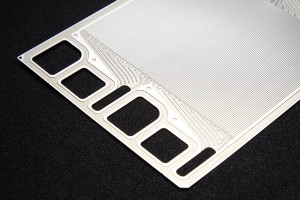

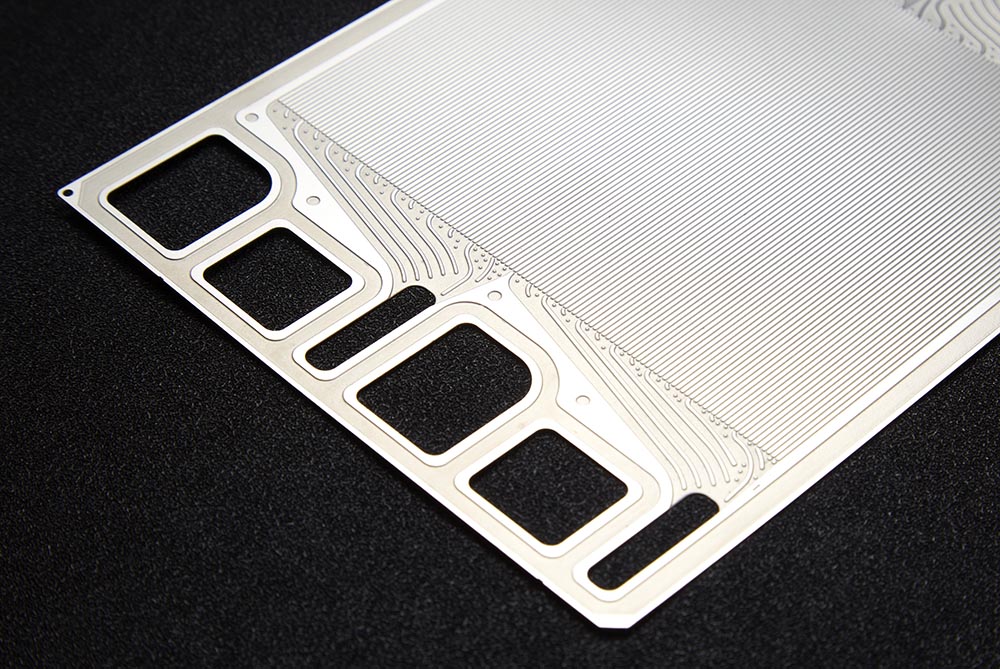

However, the small molecular size and high reactivity of hydrogen gas make it difficult to transport and store through conventional fluid mechanics. Therefore, precision channels are required to ensure the effective transport of hydrogen gas. Bipolar plates for hydrogen energy made by photochemical etching have high precision and uniformity, ensuring the smooth flow of hydrogen gas in the channel, thus improving the utilization and efficiency of hydrogen gas.

Photochemical etching is a very precise manufacturing technology that uses corrosion to manufacture micro-level channel structures on metal surfaces under illumination. This manufacturing method has the advantages of high precision, efficiency, and low cost, and can produce very small and precise bipolar plate flow channels to ensure the smooth flow and efficient utilization of hydrogen gas.

In addition to precision channel manufacturing technology, bipolar plates for hydrogen energy also need to have high corrosion resistance, strength, and stability. Currently, some new materials such as carbon nanotubes and metal-organic frameworks are widely used in the manufacturing of bipolar plate flow channels for hydrogen energy to improve their performance and reliability.

In the future development of hydrogen energy, bipolar plate flow channels for hydrogen energy will continue to play an important role. With the popularization and application of hydrogen energy, the demand for bipolar plate flow channels for hydrogen energy will also continue to increase. Therefore, future research should focus on exploring more advanced manufacturing technologies and materials to achieve higher precision and reliability.