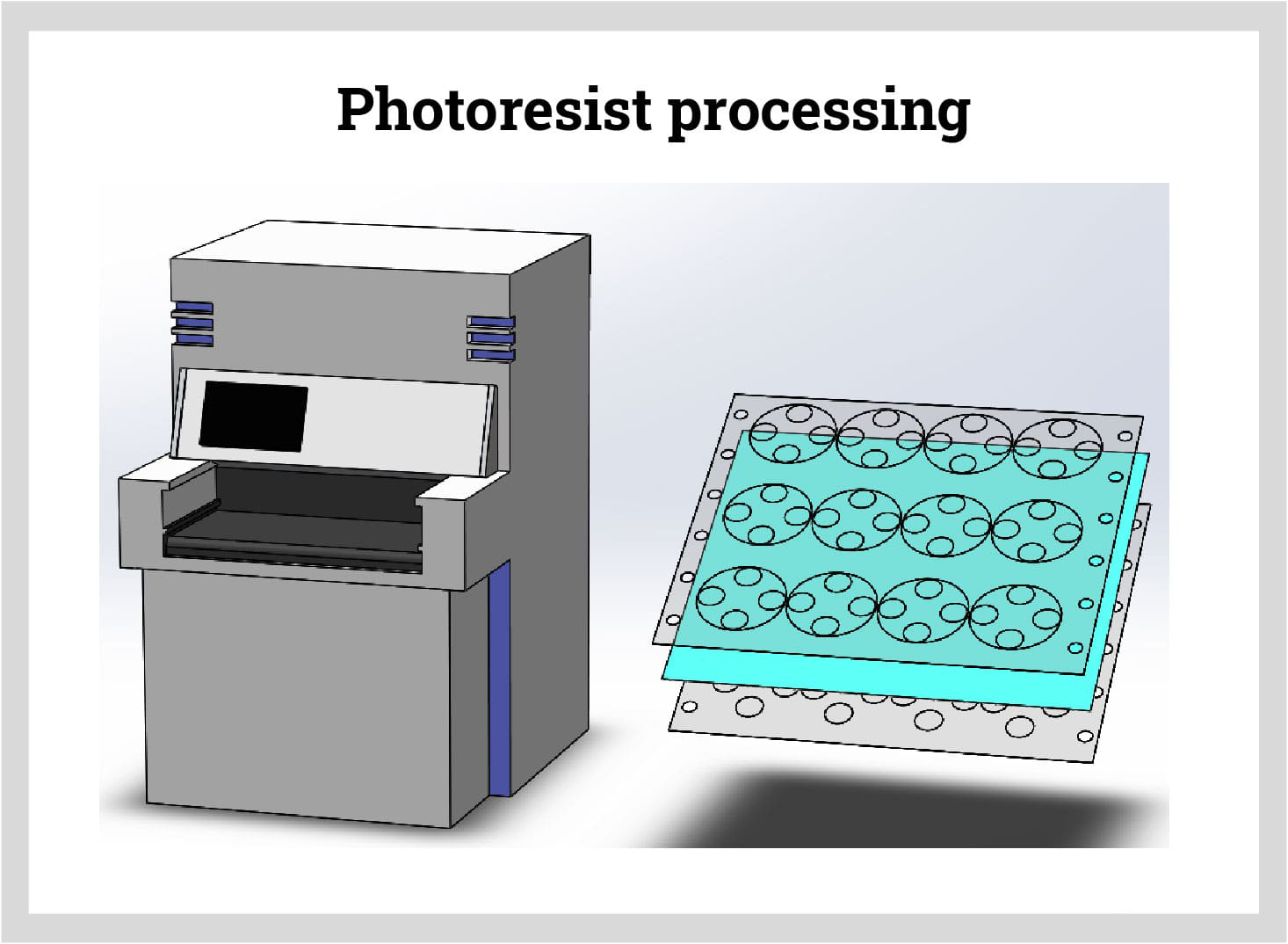

Photoresist Processing

During photoresist processing, the images from the CAD or Adobe Illustrator rendering are placed on the layer of photoresist on the metal sheet. The CAD or Adobe Illustrator rendering are imprinted on both sides of the metal sheet by sandwiching them over and under the metal. Once the metal sheets have the images applied, they are exposed to UV light that places the images permanently. Where the UV light shines through the clear areas of the laminate, the photoresist becomes firm and hardens. Black areas of the laminate remain soft and uninfluenced by the UV light.

In the photoresist processing stage of photochemical metal etching, the images from the CAD or Adobe Illustrator design are transferred onto the layer of photoresist on the metal sheet. This is done by sandwiching the design over and under the metal sheet. Once the images are applied to the metal sheet, it is exposed to UV light, which makes the images permanent.

During the UV exposure, the clear areas of the laminate allow the UV light to pass through, causing the photoresist to harden and become firm. In contrast, the black areas of the laminate remain soft and unaffected by the UV light. This process creates a pattern that will guide the etching process, where the hardened areas will remain and the soft areas will be etched away.