-

Etching

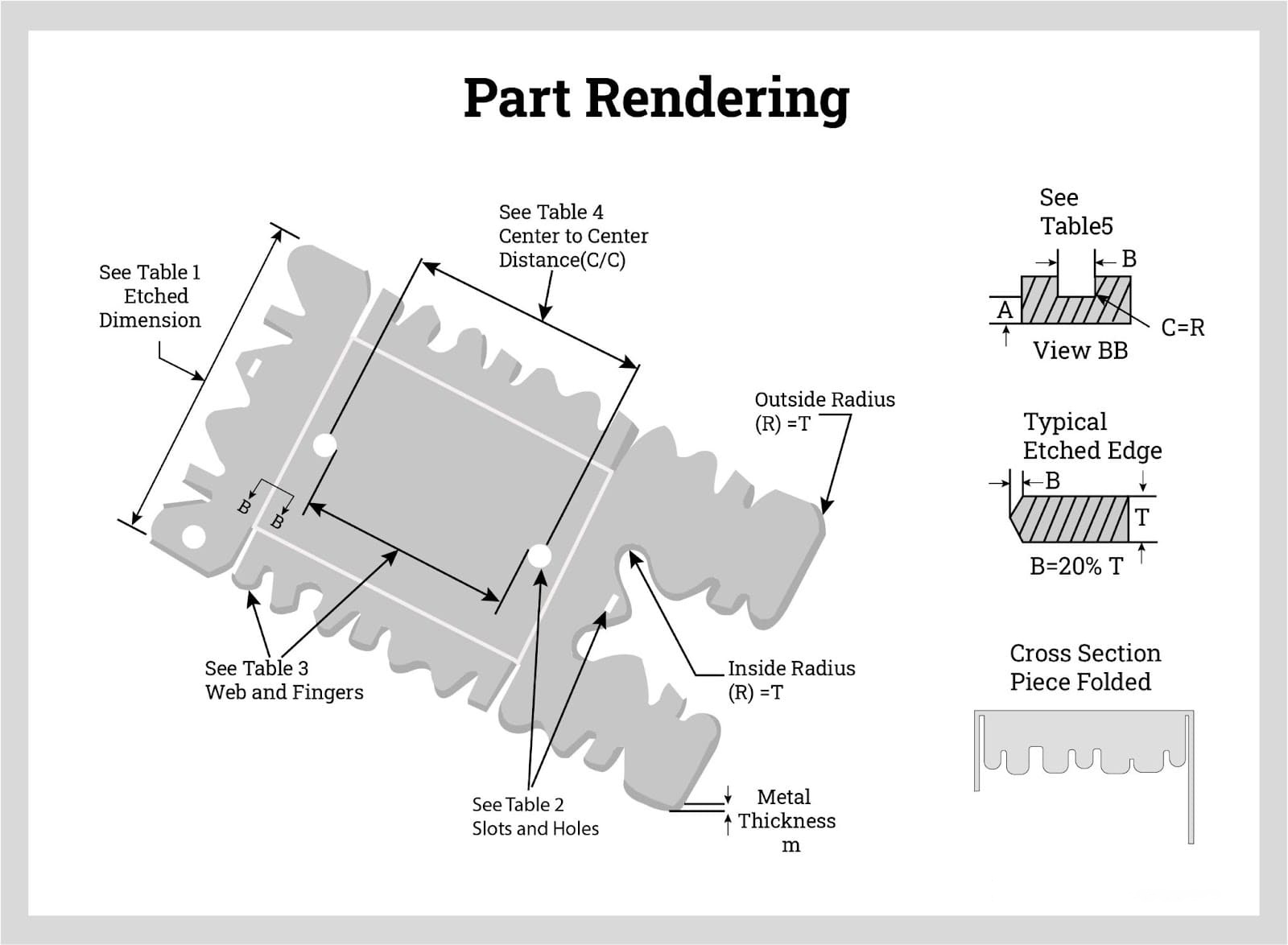

The process of photochemical metal etching begins with the creation of a design using CAD or Adobe Illustrator. Although the design is the first step in the process, it is not the end of computer calculations. Once the rendering is finished, the thickness of the metal is determined as well as the number of pieces that will fit on a sheet, a necessary factor for lowering the cost of production.

-

Stamping

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few.

-

Laser Cutter

A laser cutter’s beam usually has a diameter between 0.1 and 0.3 mm and a power of between 1 to 3 kW. This power needs to be adjusted depending on the material being cut and the thickness. To cut reflective materials like aluminum, for instance, you may need laser powers of up to 6 kW.

-

CNC

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot.

-

Welding

The weld ability of the metal refers to the adaptability of the metal material to the welding process, mainly refers to the difficulty of obtaining high-quality welded joints under certain welding process conditions. Broadly speaking, the concept of "weld ability" also includes "availability" and "reliability". Weld ability depends on the characteristics of the material and the process conditions used.

-

Surface Treatment

Surface treatment is an additional process applied to the surface of a material for the purpose of adding functions such as rust and wear resistance or improving the decorative properties to enhance its appearance.